Road tubeless liners and rolling resistance

25 November 2020

In previous tests we have shown the importance of rolling resistance on cycling performance. A tyre with a high rolling resistance will require more power to travel at the same speed, whilst a low rolling resistance tyre requires less power.

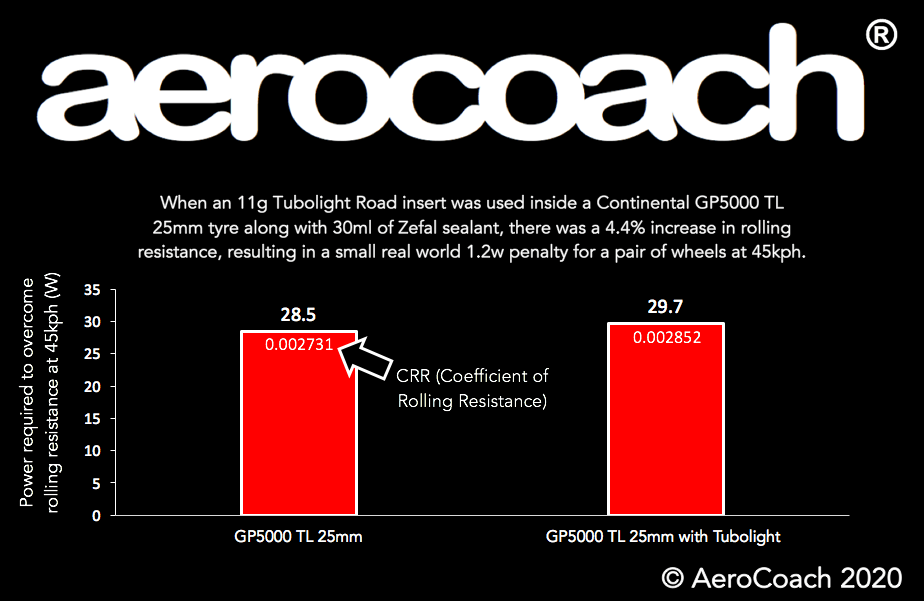

In this experiment we explored how adding a tubeless liner to a Continental GP5000 tubeless tyre affected the rolling resistance.

It has often been said that to have good cycling wheel performance, there is a "rule" that the external rim width of a wheel should be at least 105% of the width of the tyre, or that there is a simple relationship/formula that will predict the aerodynamic performance of a wheel based on rim width vs tyre width. Whilst this may have rung true with older models of wheels which shared a V shaped or flat sidewall shape, modern rims come in a range of shapes which vary in terms of their aero performance due to a number of factors, not just external rim width. Rim depth, the vertical location of maximum rim width, nose profile (at the spoke entry point), dropoff angle to nose profile and "brake track" angle are all critical components that add up to allow for a fast rim shape. The data below is a subset, taken from a wind tunnel test of deeper time trial/triathlon wheels, both with normal spokes and composite multispokes (3 and 4 spokes), exploring if there is a simple relationship between the external width of a wheel and its performance, all with the identical same tyre.

Reducing rolling resistance is imperative to improved cycling performance, particularly during high speed track cycling. A tyre with a high rolling resistance will require more power to travel at the same speed, whilst a low rolling resistance tyre requires less power. We have previous shown that top end clincher tyres, such as the FMB/AeroCoach Pista Ultra 3000 have extremely low rolling resistance. We have also found that for road tyres at road pressures, latex inner tubes are the best option for reducing Crr compared with TPU tubes. In this test we explore the difference between TPU and latex tubes but at higher, track relevant pressures and with a track specific tyre rather than a road tyre.

The new Continental Aero 111 tyre is designed to provide maximal aerodynamic advantage by use of a custom tread pattern. However there is often a tradeoff between aerodynamics and rolling resistance (Crr) in terms of how tyres are shaped and how this affects Crr, and understanding how the two combine to provide the overall fastest system is essential when looking to improve performance on the bike.

Chris Hall came to visit us at AeroCoach HQ in order to improve his bike fit on his Cervélo road bike, specifically focusing on aerodynamics for road bike time trials. Holding different positions such as in the drops, the breakaway aero position and on the hoods we explored the impact on Chris' body position and how that would relate to his aerodynamic drag.

Watch the video to improve your road bike fit for aerodynamics: Xavier and Chris discuss narrow handlebars, turned in levers, torso angle, aero helmets and more!

Aerobar extensions, whether used on a triathlon/TT bike or using a clip on system on a road bike, come in a wide variety of sizes and shapes. AeroCoach has been testing riders since 2012 and we've noticed a few trends into how you can optimally hold your extensions for aerodynamics as well as comfort. Your body accounts for around 80% of the aerodynamic drag of the bike and rider system. Your optimal stack height, extension reach and elbow width for aerodynamics will be individual and can only be determined by conducting an aero test, but as well as these variables there are differences in how riders hold their hands on extensions, and in this test we explored some general guidelines which you can follow. Don't forget, a lower aerodynamic drag will result in less power required to travel at the same speed, or for the same power will cause an increase in riding speed, when not travelling up steep gradients.

In the UK, having a front light when racing time trials is now obligatory under CTT regulations. Not only this, but also some events are conducted over long periods of time (eg. 24hrs, or multi day ultra endurance rides) and so with front lights being a necessity we explored the impact of front lights on racing aeroydnamics in the wind tunnel.